VANCOUVER -- At a time when supplies of personal protective equipment are in high demand and, in some cases, hard to come by, researchers at a B.C. university are working on prototypes for an N95 mask, which is also biodegradable.

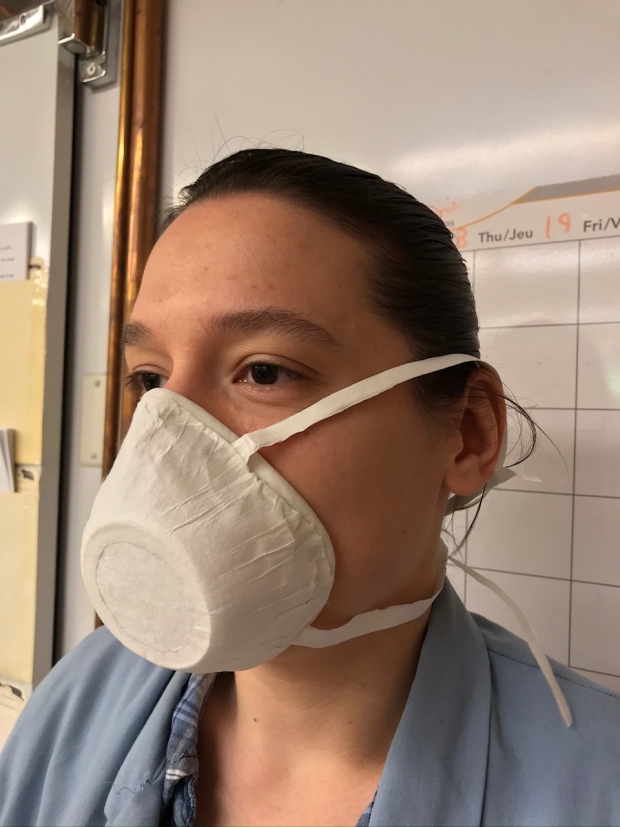

The mask, dubbed the Canadian mask or Can-Mask, has a frame made of B.C. wood fibres such as pine, spruce, cedar and other softwoods.

One of the prototypes incorporates a commercial N95 filter; the other has a filter made from wood-based products.

Chemical and biological engineering associate professor Johan Foster, from the University of British Columbia, said researchers began creating a mask back in March.

"We knew early on we wanted a solution that uses local materials, is easy to produce and inexpensive, with the added bonus of being fully compostable and biodegradable," Foster said in a news release from UBC.

- Related: UBC expert says COVID-19 vaccine possible in 12 to 18 months

- How could COVID change the modern office? A UBC prof weighs in

- Back to school: Here's what UBC, SFU have planned for the fall semester

"With millions of disposable masks and gloves already polluting city sidewalks and potentially entering our rivers and oceans, we urgently need a biodegradable option to avoid making a massive impact on our environment."

UBC BioProducts Institute director Orlando Rojas told CTV News Vancouver the environmental impact from the volume of personal protective equipment being thrown away right now could be "really, really huge."

"It's really shocking to see how many of these current masks and gloves end up in the environment, and eventually they will end up as microplastics in the oceans," Rojas said. "The sustainable use of wood, in this case fibres to make filters, makes a lot of sense."

Rojas added the institute actually produced a publication on air filtration using wood fibres back in 2008.

"It's not really a new idea. The use of fibre for filtration is known," Rojas said, and pointed to filtering water for making coffee as one example. "But it's a little more demanding in terms of the standards that are required."

Rojas said it would be possible to mass produce the wood fibre masks.

"We think there is an opportunity. The technology that we are using is already known, and we are in contact with producers of the machinery," Rojas said.

Rojas added while the cost for production still isn't known, "you can imagine this as being similar to the cost of a piece of paper."

The prototypes are now being tested, and researchers plan to apply for Health Canada certification soon.

"Our hopes are very high, but this of course is a process that needs a lot of testing, certification, so this is not for tomorrow. This would be taking several months, for sure," Rojas said. "But I think raising the awareness, announcing this possibility is important for starting partnerships."