VANCOUVER -- A small Vancouver company is bucking the trend during the COVID-19 pandemic.

Instead of struggling to survive, 3DQue is thriving, thanks to their unique 3D printing technology.

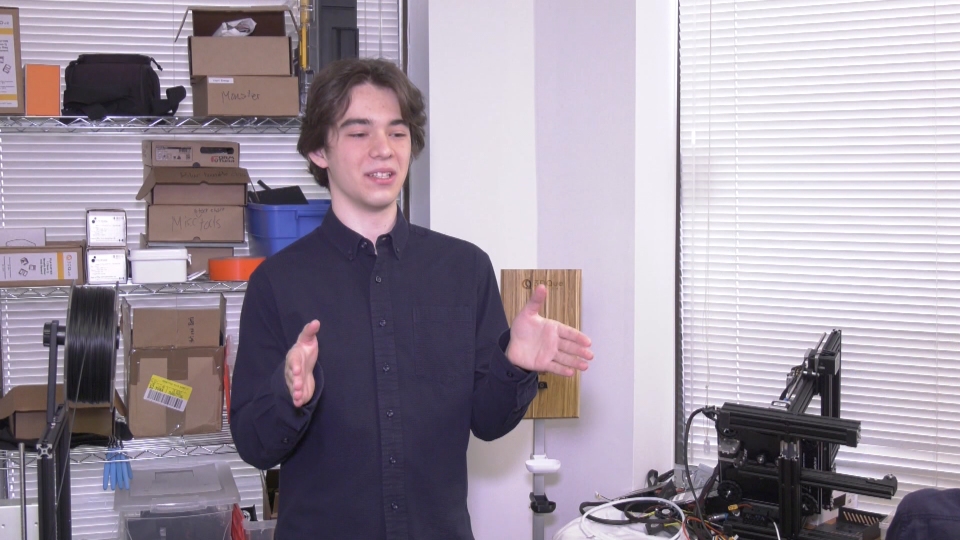

Co-founder Mateo Pekic, who is only 19 years old, bought his first 3D printer when he was in high school.

“Instantly I was captured by the magic of you have a single box, and that one box can produce any part you want,” he says, recalling that his friends at the time would ask him to print things like Yoda heads.

“Eventually, it started building from me fiddling with my own inventions to me helping my peers print and manufacture their own ideas.”

Pekic had to overcome a common challenge for 3D printing – the process is slow, and requires someone to remove and adjust the object being printed. So the teen developed software to automate the process.

“Now that you’re not babysitting the machines, making sure everything is going right, you can actually set up 40 machines to a person or 50 machines … and just have them all run automatically all night long.”

The next roadblock Pekic couldn’t invent his way out of was his age.

“To legally become a director of the company, I had to wait until I was 18,” he recalls with a laugh.

Enter Steph Sharp, a classmate’s parent with a background in start-ups, who was immediately impressed with Pekic’s vision.

“Mateo decided he wanted to start a business and then asked me if I’d come and help him run it,” Sharp says. She’s now the CEO of 3DQue, while Pekic is Chief of Innovation.

Their first installation was for Mitsubishi, and the company was in the middle of scaling up to other customers when the COVID-19 pandemic hit.

Now they’ve switched their 45 printers over to manufacturing PPE, including thousands of face shields, ear savers and automatic dispensers for hand sanitizer.

“We’re doing a lot of work with government. They’ve asked us to produce swabs, which we’re just in the process of getting approved by Health Canada,” Sharp says.

Pekic says his goal is to have 3D printing become a “viable manufacturing process, so that in your everyday lives, you’ll actually see 3D-printed products on store shelves.”

Since November 2019, the company has gone from having one employee, to 22.